Above Installation

Introduction

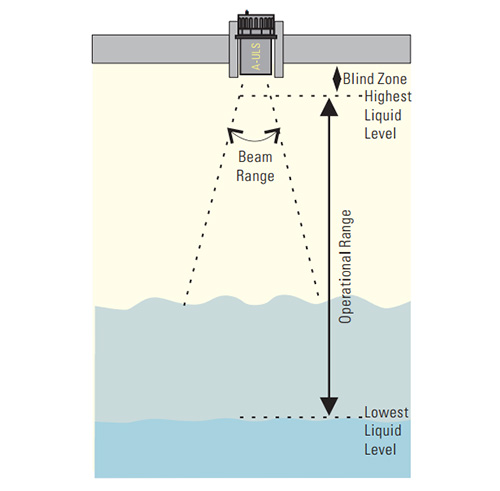

The A-ULS are innovative ultrasonic liquid level sensor families that replace float, conductance and pressure sensors but “non-contact” with dirty, sticky and scaling media in small, medium and large capacity tanks.

Applied in chemical, water and wastewater applications, these general purpose non-contact sensors are available with single and multi-function capabilities including continuous level measurement, switching and control.

They are also widely used in water treatment applications for pump control and open channel flow measurement. The ultrasonic sensor enjoys wide popularity due to the powerful mix of low price and high functionality.

Features and Benefits

– Continuous level detection

– Narrow beam angle and short blind zone optimized for both large

and small tanks

– 4 cables for simple wiring connection

RED: Power +

Black: Power –

Blue: RS485+/ RS232+ /TTL

Green: RS485-/ RS232- /TTL

– polyvinylidene difluoride (PVDF) transducer and NEMA Type 6P polycarbonate enclosure for

corrosive liquids

– UV stable for outdoor use

– Automatic temperature compensation for accurate measurement

Ultrasonic Liquid Level A-ULS Technical parameters:

| Model | A-ULS-20 | A-ULS-30 | A-ULS-50 | A-ULS-80 | A-ULS-A0 | A-ULS-A5 |

|---|---|---|---|---|---|---|

| Measure Range | 0.2-2m | 0.12-3m | 0.15-5m | 0.15-8m | 0.35-10m | 1-15m |

| Output | RS485 / RS232 / TTL / 4-20mA | |||||

| Mounting | Thread M30*1.65mm | |||||

| Beam Range | 7° ± 2° | 7° ± 2° | 7° ± 2° | 7° ± 2° | 12° ± 2° | 12° ± 2° |

| Ambient Temperature | -40° to 80°C | |||||

| Process Temperature | -20° to 60°C | |||||

| IP Protection | IP67 | |||||

| Case Material | PVDF/ABS | |||||

| Cable Length | 20cm | |||||

| Compliance | CE, RoHS | |||||

| OEM Service | Yes. Can be Customized | |||||

| Low Power | Can be customized to power with battery and for IOT solution | |||||