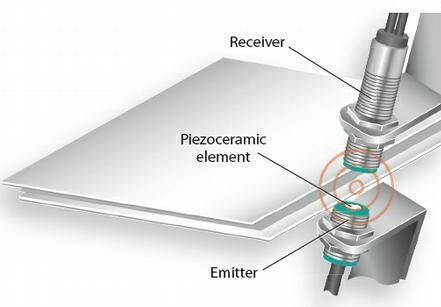

Ultrasonic Double Sheet Sensor (double tension detection) system is designed based on the principle of ultrasonic, so it is free from the vibration, material and color of the object being inspected. The principle of double sheet detection is based on the reduction of ultrasonic signal strength by one or two materials.

Completely overcome the shortcomings of other similar products such as photoelectric, mechanical and other similar products , such as transparent film and thin metal sheet, solar silicon chip, PCB circuit board, coating machine thin sheet and so on can be accurately detected.

It is widely used in paper-making,stamping, instant noodle packers, food packaging, solar wafer production equipment, coating machine, automatic binding and other industries.

Ultrasonic Double Sheet Sensor TA0200DSS Basic specification

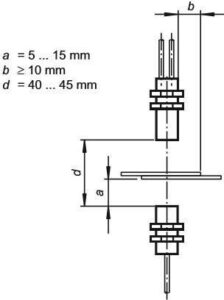

Sensing range: 20 … 60 mm

Optimal distance : 45 mm

Sensor frequency: 200 kHz

Indicators/operating means

LED Blue Indication: No sheet detected (Air)

LED Green Indication: single sheet detected

LED Red Indication: double sheet detected

Electrical specifications

Working voltage:18 … 30 V DC, Ripple 10 %pp

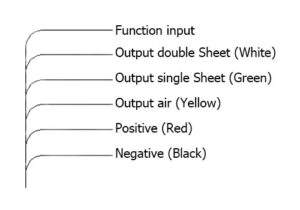

No-load supply current I0 < 80 mA Input type: Function input

0- level : -UB … -UB + 1 V

1- level : +UB -1 V … +UB

Pulse length: 100 ms

Impedance: 4 k

Output type: 3 switch outputs NPN , NC

Rated operating current: 3 x 100 mA short-circuit/overload protected

Voltage drop Ud: 2 V

Switch-on delay ton approx. 15 ms (shorter response time on request)

Switch-off delay toff approx. 15 ms (shorter response time on request)

Protection grade: IP67

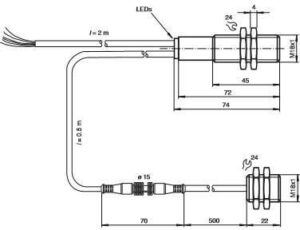

Connection type: 2 m, PVC

Core cross-section: 0.14 mm2

Housing: Nickel plated brass; plastic components: PBT 304

Transducer: Stainless steel

Weight: 150 g

Cable Connection

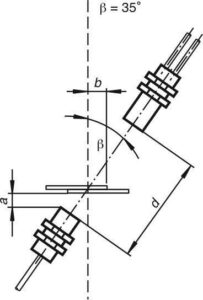

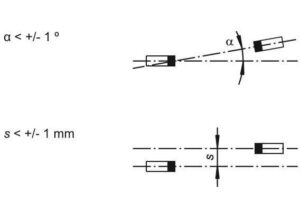

User Guidance